Tel:400-0058-999

Add:No. 2200, Section 3, South Street,Wafangdian City, Liaoning Province, China

Tel:0411-85647733

Fax:0411-85647666

Website:xmwss.cn

Customised linear axes are 3D-printed to order

Release Time:01 Mar,2017

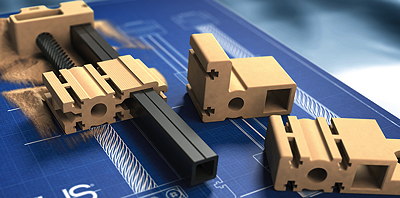

The engineering plastics specialist igus has launched a service that will 3D-print bespoke carriages and end-blocks for linear axes to customer requirements. The components are printed using a laser sintering process within 48 hours of an order being placed, using a plastic said to be three times more abrasion-resistant than conventional SLS (selective laser sintered) materials. The printed items can be assembled with a handful of other components to produce a customised axis “within seconds”, according to igus. As well as producing axes as one-offs or in small batches, the new process will allow machine-builders to test new ideas for profile designs, stroke lengths or fastening options. The parts, printed in a high-performance tribo-SLS material called iglidur I3, can be produced in complex shapes. “The purpose of developing the SLTI3 lead-screw unit was to enable quick and easy assembly, with the maximum possible variability,” says igus' UK dry-tech director, Robert Dumayne. “We also reduced the component count, compared to our standard SLT module, enabling it to be assembled in seconds.” The new 3D-printing service produces customised components for linear axes, within days

The assembled axes are self-lubricating and maintenance-free. The side-mounted leadscrew configuration is available in manual or motor-powered formats.

The new 3D-printing service produces customised components for linear axes, within days

The assembled axes are self-lubricating and maintenance-free. The side-mounted leadscrew configuration is available in manual or motor-powered formats.

Mobile Website

Wechat Platform

Wafangdian GuangyangBearing Group Co., Ltd.

Equipment & Capability

Copyright@2017Wafangdian Guangyang Bearing Group Co., Ltd.